- Home

- Factory Production Tour

Factory Production Tour

A Full-Spectrum View of MiMA Factory

01 - Global Sourcing for Uncompromising Quality in MiMA Forklifts

- Choose premium german KRUPP channel steel.

- Up to 100mm thickness profile for maximum durability.

- Custom profiles, domestic or imported, free for you to choose.

- Full transparency on material sources.

02 - MiMA Blanking Workshop: Quality from the First Cut

At MiMA, we know that forklift reliability begins with the very first cut. That’s why our Blanking Workshop employs six specialized technologies, guaranteeing precise tolerances and clean edges for every component. This exacting commitment translates directly to longer-lasting parts, peak forklift performance, and reduced downtime for your operations.

03 - MiMA Metal Workshop: Precision, Power, and In-House Expertise

We craft critical forklift components in-house, ensuring the precision and reliability you demand. To handle complex and oversized parts, we deploy the massive 5-meter gantry milling machines – your guarantee of exceptional capability.

04 - Inside the MiMA Welding Process

We marry skilled craftsmanship with advanced robotics to ensure our components deliver unmatched strength and durability. Here’s what sets us apart:

- Precision Alignment: Our technicians utilize specialized fixtures for perfect pre-weld setup, guaranteeing product quality.

- Robotic Efficiency: Welding robots streamline production with the output of four skilled welders, driving rapid turnaround and consistent quality.

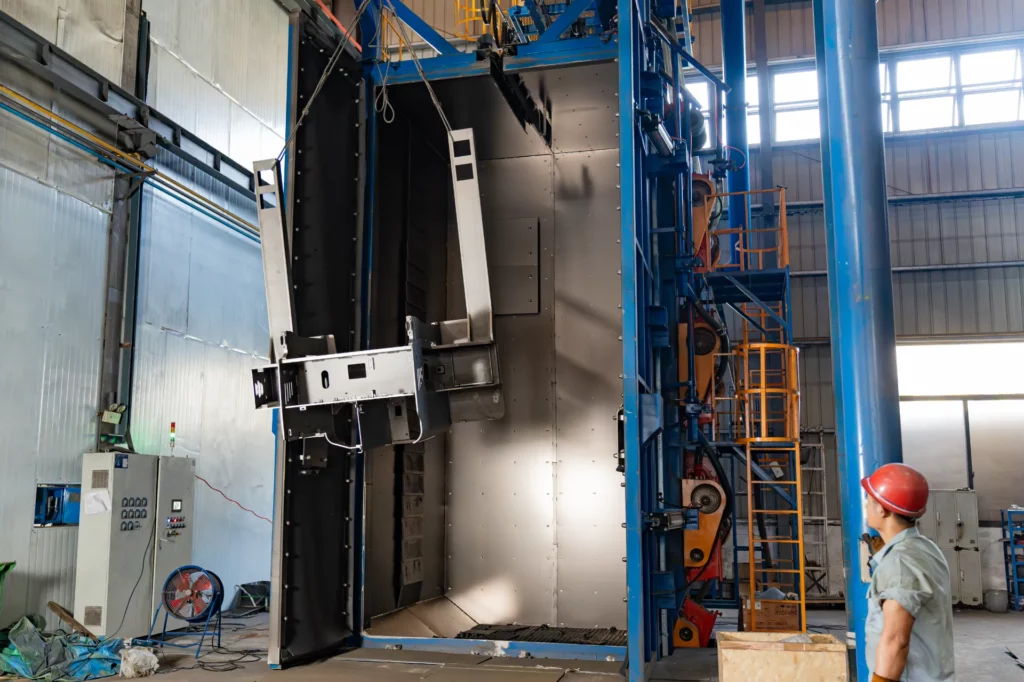

05 - MiMA Painting Workshop: Durable Finishes, Eco-Conscious Choices

Our commitment to quality doesn’t end with fabrication. Our painting process guarantees your investment will look great and last for years to come, while minimizing environmental impact.

Meticulous Preparation: Shot blasting and sanding ensure flawless paint adhesion. We then apply a meticulously smooth putty layer, creating the ideal base for optimal final coat performance.

06 - Precision Assembly, Rigorous Testing

Each vehicle is assembled to its model-specific requirements, with the nameplate signifying rigorous quality inspection and adherence to manufacturing standards.

Testing Procedures:

- Weight Tested (1.33x Capacity): Safety is paramount. We rigorously test each forklift to handle loads exceeding its design limits.

- Incline Tested: Stability and power on slopes up to 15 degrees ensure your forklift handles any terrain.

- Straight-Line Accuracy: Experience smooth operation and efficient material handling.