If you’re looking for warehouse handling and stacking equipment to optimize your storage space, the MiMA VNA forklift can help you maximize storage capacity without adding land costs. Or you want to move goods in your warehouse faster to optimize your efficiency. Electric very narrow aisle forklifts can do it all.

Electric VNA(very narrow aisle) forklifts are helping more and more warehouses increase storage capacity and efficiency between tight spaces while maintaining or even improving safety and productivity. They have been specifically designed for this ultra-narrow working environment and offer many benefits over regular forklifts.

In this article, we will talk about the definition, benefits, types, and other essential features of electric VNA forklifts to help you find the best solution for your needs.

1. Things You Should Know About VNA forklifts:

1. What is the electric VNA forklift?

Very Narrow Aisle Pallet Racking can be called VNA, a compacted version of standard pallet racking, aiming to maximize warehouse capacity without expanding space.

Electric Very Narrow Aisle (VNA) forklifts are designed for stacking and order picking in high-density warehouses and narrow aisle areas.

2. What kind of working conditions does the electric VNA forklift apply to?

The narrow aisle width is typically between 1,500 mm and 1,800 mm, which means the work aisle width can be narrowed to 1.5 meters and save up space at least 40%. However, considering all other technical and realistic factors, the most common aisle width for shelving is 1.6 meters.

3. Where are VNA forklifts commonly used?

VNA forklifts are specialized trucks designed to operate in ultra-narrow aisles, mostly indoor warehouses and distribution centers. It provides high-level dense storage solutions for the VNA warehouse. Electric VNA forklifts are essential for high-density storage applications and enhance warehouse productivity.

VNA forklifts can deal with both full pallet handling and order picking. The ever-growing need for more efficient use of space has led many companies to change to VNA solutions.

MiMA electric VNA forklift excels in situations requiring precise maneuverability and vertical lift capabilities, often used in retail, manufacturing, and distribution centers to optimize space and enhance efficiency.

2. What are the benefits of VNA forklifts?

Increase Productivity:

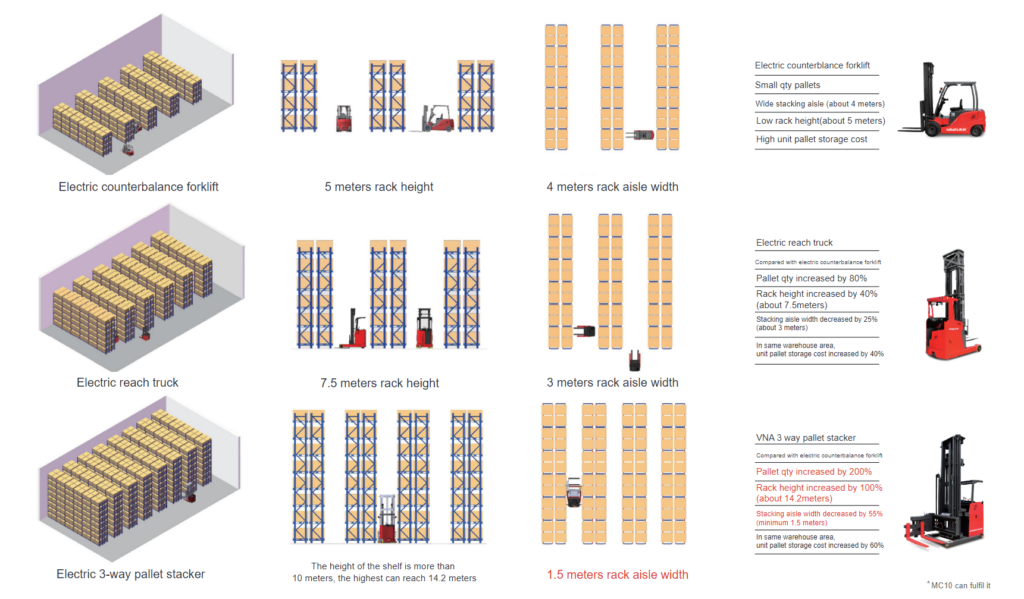

MiMA VNA forklift solution can greatly increase your warehouse utilization and productivity. It can improve the storage capacity by 200% possible by these two methods:

- Reduce the aisle width:

Compared to conventional reach trucks or pallet stackers requiring aisle widths of over 2.7m, most companies providing VNA solutions can reduce the width to less than 1.8m. However, the MiMA Forklift can ultra-narrow the width measuring around 1.6m.

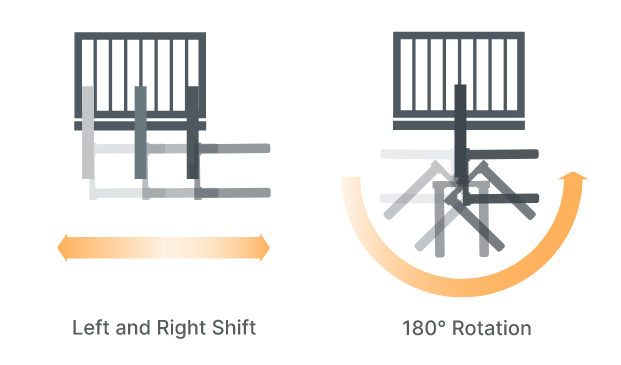

MiMA 3-way pallet stacker is equipped with a specially designed fork, it can achieve left and right side shifts + 180° rotation. That means MiMA VNA forklifts do not need to change the vehicle’s direction to stack cargo on both sides. The aisle width is almost the same as the vehicle width.

- Raise the rack height:

VNA racking can also be constructed significantly higher. With sufficient roof height, it allows stacking heights of up to 16800mm.

MiMA VNA forklifts utilize a robust and precise mast structure made of high-strength steel, which minimizes deflection and deformation when stacking, especially at high positions. The mast features a semi-closed rectangular frame with a slant rod for added strength and precision, allowing for higher racking.

Maximize Efficiency:

MiMA 3-way pallet stackers provide two navigation modes: Mechanical guide rail mode and optional magnetic navigation mode.

- Mechanical Guide Rail Mode: Guide rails installed at the aisle base guide vehicles along the tracks, ensuring safe and efficient operation.

- Magnetic Navigation Mode: By eliminating the need for ground guide rails and bottom beams, goods can be placed directly on the floor, reducing warehouse construction costs.

When driving in the aisle, the forklift does not require adjusting the vehicle’s direction, making operation simple and flexible. This not only improves work efficiency but also ensures safety during high-level stacking.

Simply put, the forklift follows magnetic strips to travel in a straight line within the aisle, reducing operational difficulty and working time.

Both modes improve efficiency by streamlining navigation and minimizing the need for manual adjustments, enhancing overall workflow.

Improved Safety:

Safety is the priority not only in operation but also in the whole process of forklift design and production. Many companies are committed to achieving higher safety, and the safest is usually the most popular. MiMA Forklift owns many patents and technical advantages for electric VNA forklifts, especially from the perspective of safety.

MiMA 3-way pallet stacker and articulated forklift use a narrow mast, open slide, and driving wheel angle display to provide operators with excellent visibility and easier operation.

Not only improving the view to ensure safety during the operation but also equipped with many other advanced functions to protect the operators. For example, height pre-selection, end-of-aisle deceleration, and emergency stop button to meet the demands for efficiency and safety.

Unparalleled Reliability:

Additionally, the integrated large cabin and specially designed side shift carriage enhance fork stability and reliability.

The MiMA 3-way pallet stacker series is designed for narrower aisles, and higher lifting heights with excellent visibility, helping improve warehouse utilization and simple goods handling processes. With the MiMA three-way stacker, you can maximize your space, simplify the process of cargo handling, stacking, and picking, and improve working efficiency.

The 3-way stacker series adopts an imported American Curtis controller, which has excellent performance, stability, and reliability. A variety of driving modes and configurations to meet different working conditions and industry needs, providing more choices for your warehouse handling solutions.

3. What are the types of electric VNA forklifts?

Man-up turret truck

This is a 3-way pallet stacker where the operator ascends with the mast in the cab. The biggest advantage is excellent visibility and improved stacking efficiency.

There are not many manufacturers in China who can produce man-up turret trucks, because of the high demand for advanced technology and indispensable upgraded protection functions for safety. One of them is MiMA Forklift.

MiMA’s man-up forklift is a robust and versatile model designed for optimal safety and efficiency in high-level operations. It features a foldable, height-adjustable seat that doubles as a backrest when folded, giving your operator more comfort and reducing fatigue during order picking.

The forklift offers excellent load capacity at height, with minimal sway for greater stability and safety. With a maximum lifting height of 14.2 meters and an ergonomic design, it provides ample space for safe and efficient order picking, especially for large-sized goods.

MiMA also integrates a German-imported GESSMANN control handle, enabling easy, single-handed operation, and features comprehensive safety mechanisms, including pressure relief valves and emergency descent ropes, ensuring the operator’s safety in various scenarios.

Additionally, MiMA’s efficient motor system consumes less power while maintaining fast travel and lift speeds, resulting in higher operational efficiency and longer motor life.

Man-down turret truck

A man-down turret truck means that the driving cabins do not lift with the mast during the operation. Compared to man-up turret trucks, there are relatively more manufacturers in China that can produce this type of forklift.

The MCA16 narrow aisle forklift by MiMA is a compact, high-performance model designed for narrow spaces. It features a maintenance-free full AC system, an imported controller, and pure electronic steering for easy operation, ensuring rapid response, stability, and safety.

The H-type mast enhances the load capacity of 1.6 tons, lifting height of up to 15800mm (MCC16 for double-deep racking), and good visibility, while the powerful drive motor and all-wheel electromagnetic braking maximize efficiency and safety.

The MCA16 also includes an RFID-based slowing and stopping system at aisle ends, ensuring secure and confident operation. With low energy consumption and zero emissions, it’s ideal for stacking heavy-duty tasks in very narrow aisles.

The MCA16’s pure electronic steering and all-wheel electromagnetic braking work in perfect harmony, maximizing operational efficiency and safety. With its low energy consumption and pollution-free design, this forklift is engineered to meet the demands of heavy-duty conditions while delivering consistent, reliable performance.

Articulated forklift

There is another type of forklift solution that deals with narrow aisle challenges. Its working aisle is a little wider than a 3-way pallet stacker, but it features excellent adaptability to working environments and is not limited to indoor stacking.

Equipped with solid rubber tires, this versatile machine is suitable for both indoor and outdoor use, including on inclines. Its multifunctional design reduces the need for additional vehicles and enhances overall operational efficiency.

MiMA’s articulated forklift is designed to maximize space efficiency with a working aisle width of just 1.9 meters. Ideal for high-rack stacking, it offers a lift height of up to 12.5 meters. The forklift’s mast can pivot up to 210°, making stacking in narrow aisles more convenient while maintaining excellent visibility.

MiMA Articulated forklift can efficiently transport goods from outdoor to indoor rack positions, enabling precise stacking and significant time savings.

4. What is the difference between various types of MiMA VNA forklifts?

Reach truck VS VNA forklift

Reach trucks are designed for medium-width aisles. Their extendable forks can reach into racks without the need to enter the aisle, making them ideal for handling lighter loads. For warehouses that don’t have strict space constraints, reach trucks are an efficient choice, especially for medium and low-level rack storage.

MiMA’s VNA forklifts, like the three-way pallet stackers, are built for narrow aisles. They feature forks that can rotate left and right without moving the body, making them perfect for high-density storage. For example, MiMA’s VNA forklifts can operate in aisles as narrow as 1.5 meters, handling more loads in tighter spaces compared to reach trucks.

Counterbalanced truck VS VNA forklift

Counterbalanced trucks are ideal for wider aisles, using a rear counterweight to handle heavier loads. These forklifts are suitable for warehouses with heavier items that require frequent movement and stacking. In addition, it can be used in various working conditions, bringing you a one-stop warehouse experience. However, they typically need aisles at least 3 meters wide.

VNA forklifts excel in tight spaces. They can operate efficiently in narrow aisles, maximizing storage density without sacrificing speed or safety. Unlike counterbalanced trucks, VNA forklifts reduce aisle width requirements and increase warehouse efficiency, especially for higher-rack storage.

Articulated Forklift VS VNA forklift

Articulated forklifts offer flexibility for various warehouse needs, particularly when handling narrow aisles with larger turning radii. It can also be used indoors and outdoors. These forklifts have rotating bodies that allow for wider-angle turns in tight spaces.

VNA forklift: MiMA’s VNA forklifts are more optimized for very narrow aisles. For example, the MCA16 VNA forklift can handle loads on both sides without needing to turn. In warehouses where space is extremely limited, VNA forklifts are more efficient since they minimize the turning space required by articulated forklifts.

What is the comparison and advice for choosing an electric VNA forklift and other warehouse forklifts?

MiMA’s electric VNA forklifts are perfect for high-density storage environments, especially for aisle widths under 1.8 meters. These forklifts are equipped with precision control systems and efficient electric drives, making them both maneuverable and energy-efficient. MiMA’s electric VNA forklifts are ideal for maximizing storage space in tight, high-rack warehouses.

If your aisles are wider or you need a forklift that can be used both indoors and outdoors, MiMA’s other model forklifts might be a better fit, depending on your specific needs.

5. What are VNA forklift top brands?

Toyota Industries Corporation, based in Japan, is one of the top VNA truck manufacturers. Toyota is known for its innovative and high-quality products.

Their advanced VNA series, based on the BT Vector A-series, with an articulated chassis for enhanced stability and space-saving aisle transfers, maximizing warehouse storage.

Hyster-Yale, Inc. (HY), through its wholly-owned operating subsidiary, Hyster-Yale Materials Handling, designs, engineers, manufactures, sells and services a comprehensive line of lift trucks, attachments, aftermarket parts, and technology solutions marketed globally primarily under the Hyster® and Yale® brand names. This company has a history of over 100 years.

Linde Material Handling develops high-performance material flow solutions tailored to individual customer needs, with which users are able to achieve sustainable competitive advantages. The company is one of the world’s largest manufacturers of forklift trucks and warehouse equipment and has been setting standards for solutions for industrial trucks, fleet management, driver assistance systems, and service offerings for more than 50 years.

6. Notes you need to focus on when purchasing

How suppliers like MiMA Forklift can meet your needs

1. Warehouse layout

(Warehouse established vs. Warehouse not yet established)

When considering warehouse layout during the purchase process, whether your warehouse is already established or still in the planning stages, several key factors should be noted:

A: Established Warehouse

Maximizing existing space: Evaluate your aisle width and ceiling height to determine if VNA trucks could help maximize your space without expanding.

Floor design: Consider if your existing floor can support the delicate operations of narrow aisle trucks. It should be smooth and well-maintained to avoid disruptions.

Guidance system compatibility: Ensure that the layout can adapt to the necessary guidance systems for VNA trucks, such as wire or rail guidance.

B. Warehouse not yet established

Optimal layout design: In a new warehouse, you can easily design an optimal layout from the start. Determine the ideal aisle width and ceiling height that will accommodate your desired storage density and workflow. Manufacturers can guide the best solution with their VNA trucks.

Future-proofing: Consider the potential need for expansion or changes in storage systems. Designing a versatile layout with adjustable racks and flexible zoning can help you adapt to future needs.

Order picking and flow: Decide where order picking will take place and how it will flow through the warehouse. Ensuring a smooth transition from the VNA storage to the horizontal transport zone.

How suppliers like MiMA Forklift can meet your needs:

- Customization: MiMA Forklift can help you customize your warehouse layout, whether you’re working with an existing structure or starting from scratch. Our expertise in VNA trucks and warehouse solutions ensures that your space can be used efficiently.

- Equipment selection: MiMA offers a range of VNA trucks that are designed to maximize space while providing the stability and maneuverability needed for narrow aisles.

- Guidance and support: MiMA can also assist with selecting the right guidance systems and designing a layout that integrates with your operations, ensuring that your warehouse runs smoothly from day one.

2. Customization

For standard forklifts:

VNA forklifts can be customized to adapt to various cargos, racks, lift heights, and warehouses of ultra-low temperatures.

A specific forklift model can be customized to lift heavier cargo to higher lifting heights to adapt to your goods’ weight and warehouse layout, within realistic considerations including limits of safety and technical support.

In addition, equipped with an enclosed driving cab, heater, and special hydraulic system components for cold storage, MiMA electric forklifts can be customized to operate efficiently in environments as low as -25°C. They are ideal for moving in and out of cold storage and handling tasks like loading, unloading, and stacking fresh products, making cold chain warehousing possible and reliable.

VNA forklifts can also be equipped with extra components to achieve flexible DD racking(double-deep racking) stacking. A client case of a Man-up turret truck is already specially customized for DD racking. The unique double-deep telescopic fork design integrates with the MiMA man-up turret truck, allowing efficient operation in very narrow aisles (VNA). This enables precise storage and stacking of goods on the rear rows of double-deep racks, significantly increasing warehouse storage density and turnover rate.

For AGV customization:

3. What is AGV?

AGV stands for Automated Guided Vehicle, also known as an automatic guided transport vehicle or unmanned transport vehicle. An AGV can follow a set guidance path using an automatic guidance system, allowing it to automatically complete tasks such as picking up and placing goods under the command of a control system. It is a transport device equipped with safety protection and various transfer functions.

The essence of a Forklift AGV is that it is an AGV with navigation, positioning, autonomous driving, and automatic handling functions, while also possessing the large load capacity characteristic of a forklift.

4. What are the control systems and navigation methods of AGV?

Host Control System: The host control and scheduling system includes auxiliary hardware configurations such as radar, navigation instruments, and audio-visual alarms.

Forklift Body Control System: This system consists of controllers for driving, steering, and pump operations, along with corresponding actuators like drive motors, steering motors, lift control motors, and sensors such as encoders and limit switches. It facilitates basic actions like moving, steering, and lifting the forks.

Some manufacturers of traditional forklifts, such as Toyota, and MiMA, have the ability to provide AGV forklift bodies for customers who focus on the designing of electronic software, thus making cooperation to produce driverless and efficient automated guided vehicles.

Common navigation methods for AGVs include electromagnetic navigation, magnetic tape navigation, optical navigation, natural navigation, laser navigation, inertial navigation, image recognition navigation, and GPS navigation.

5. How can the MiMA AGV forklift body fit your intelligent warehouse needs?

The MiMA forklift team has extensive experience in AGV projects. We prioritize meeting your expectations and providing the most suitable options. The reason why MiMA customized AGV forklift body is your ideal choice:

- Experienced technicians and sales engineers

- Tailored solutions for modern logistics needs

- Proven reliability and cost-effectiveness

- Enhanced performance in various scenarios

As MiMA Forklift continues to push boundaries in AGV forklift technology, we hope to partner with more businesses and deliver solutions that drive success. If you are searching for an AGV body suitable for your specific warehouse, choose MiMA Forklift.

6. Cost

MiMA Forklifts’ price ranges from ¥5,000 to ¥300,000, depending on the model that suits your needs for cargo types, sizes, weights, lift heights, and other working conditions. For instance, an electric pallet truck typically costs between ¥5,000 and ¥15,000. For articulated and multi-directional forklifts, which feature advanced technology and electric components, the price ranges from ¥20,000 to ¥30,000.

All the prices above are comparatively cost-effective compared with other companies in China. Because of the low rent cost of land and abundant and low-cost labor, our price is much lower than American and European brands, even after added with tariffs and shipping fees.

7. Warranty

Forklift warranties tend to be quietly standard throughout the material handling industry. A typical new forklift warranty covers the first 12 months or 2,000 operating hours, whichever comes first, 3-way pallet stackers included, of course.

It offers customers protection against manufacturing defects, failures, and other issues that should not arise during the first year under normal operating conditions. While most manufacturers offer warranties that are quite similar, there can be some differences. It’s important to remember that even with the best warranties, manufacturers may differentiate between forklift classes (Class I, II, III, IV, V), and these classes may have different time, hours, and usage limitations due to their distinct characteristics.

At MiMA Forklift, we offer superior warranties compared to most manufacturers. For smaller, lower-priced models like pallet trucks, standard stackers, and tow tractors, the warranty covers 18 months or 2000 hours, whichever comes first. For other models, including 3-way pallet stackers, electric counterbalanced forklifts, articulated forklifts, and order pickers, the warranty extends to 24 months or 2000 hours.

Hence, the warranty time of a typical 3-way pallet stacker is the first 24 months or 2000 working hours.

8. Delivery time

The delivery time for MiMA’s VNA forklift depends on factors such as shipping, logistics, and specific customization requirements.

On average, delivery may take between 5 to 9 weeks from the time of order confirmation. For a more accurate estimate, don’t hesitate to contact our sales team.

9. What is the main difference between MiMA and other manufacturers?

MiMA’s main difference compared to other manufacturers lies in its focus on customization and innovation within the electric forklift industry. MiMA excels at creating tailored solutions, particularly in the realm of Automated Guided Vehicles (AGVs) and very narrow aisle forklifts (VNAs), meeting the unique needs of modern warehouse logistics.

MiMA forklift offers a wide range of specialized forklifts, including models like the MC, MCA, MCC, and MJ series with advanced safety for narrow spaces and dense storage upgrades. Our commitment to quality, safety, and customer-focused customization sets us apart from competitors.

7. The Operation and Maintenance:

1. How to operate an electric VNA forklift to ensure safety?

Everyone needs proper training under safe guidance before he/she begins to operate a forklift.

To operate an electric VNA forklift safely, start by performing a pre-use inspection to check for any potential issues.

Ensure the forklift is in good working condition, especially the tires and forks.

Always wear your seatbelt and adjust the seat for comfort and control.

Use the operation panel and handle effectively to control the forklift’s movements—forward, backward, side-driving, and fork tilt/lift/lower.

Keep the load at a safe height for visibility and stability.

Never exceed the forklift’s weight capacity, and avoid carrying passengers.

When finished, turn off the forklift and remove the key.

2. What does the daily maintenance of the electric VNA forklift include?

Daily maintenance of an electric VNA forklift includes several key tasks.

First, clean the forklift using a damp cloth, focusing on areas like the forks, mast, and battery terminals. Avoid using water directly, especially on electrical parts.

Second, inspect the chassis and wheels for wear or damage, and check the tightness of screws, wire harnesses, and hose connections every 100 hours of use.

Third, lubricate moving parts like the mast, gears, and bearings weekly, ensuring they have enough grease.

Lastly, regularly clean the battery, avoid deep discharges, and charge it when the battery level reaches 20%.

Following these steps will help keep the forklift in good working condition.

8. More FAQs:

1. What is the average lifespan of an electric forklift?

The average forklift working hours per year are usually between 1,000 and 2,000. In general, forklifts are expected to last about 10,000 hours. This works out to about 5 years, based on an 8-hour, 5-day workweek.

It’s very rare to find a forklift truck that continuously works for more than ten years. If so, the price of every single forklift is very expensive. Brands like MiMA can provide cost-effective forklifts with an average lifespan of about eight to ten years.

2. The name “electric VNA forklift” was first used in which year by which company?

In 1954, a breakthrough came when British company Lansing Bagnall developed the first narrow-aisle electric reach truck.

This forklift could navigate in tight spaces while also lifting 50 feet into the air.

Ever since then, manufacturers have experimented with numerous narrow aisle forklift designs to keep up with changing warehouse footprints.

3. Automated VNA forklift: Is the VNA forklift used for the AGV system?

The answer is yes! Its name is “Automated VNA forklift”. This driverless automated VNA truck can operate in very narrow aisles while performing excellent handling and stacking operations.

Imagine you can save on labor costs, place more racks, and improve safety and precision all at one time!

Some manufacturers in China can provide all AGV forklift bodies for all types of forklifts, such as electric reach trucks, multidirectional forklifts, pallet trucks, and so on.

MiMA Forklift is dedicated to AGV forklift body production and AGV customization. This company can customize its automated VNA forklift to your specific electrical software. If you are looking for a cooperation opportunity with an AGV forklift bodies provider, MiMA Forklift is worth considering.

Conclusion:

With the right VNA forklift, you can unlock the full potential of your storage space, optimize workflows, and ultimately drive greater success in your logistics operations.

Choose MiMA VNA Forklift, your warehouse deserves a large capacity and higher efficiency!